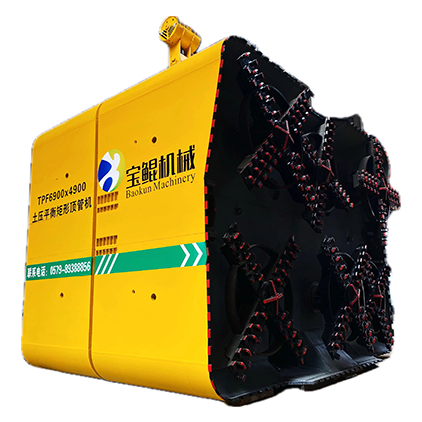

Rectangular Pipe Jacking Machine

1. Suitable for ordinary soil, silt layers, silt layers and other geological formations. Widely used in underground pipe galleries and pedestrian walkways.

2. Adopting a multi disc design to reduce cutting blind spots in rectangular cross-sections. It is easy to control the direction during top-down construction to ensure the stability of the excavation face. Adopting the method of soil pressure balance to reduce the problem of large section settlement.

3. The soil is discharged using a screw conveyor (winch) to transport the soil (close to its original state) cut by the cutterhead into the machine, and then transported to the surface by a soil truck. Reducing the pollution caused by mud discharge is a relatively clean and environmentally friendly construction process.

4. Adopting advanced industrial control technology to achieve remote safe operation. Through the PLC data link, the operating system safely controls the pipe jacking machine on the ground and real-time observation equipment for real-time data underground.

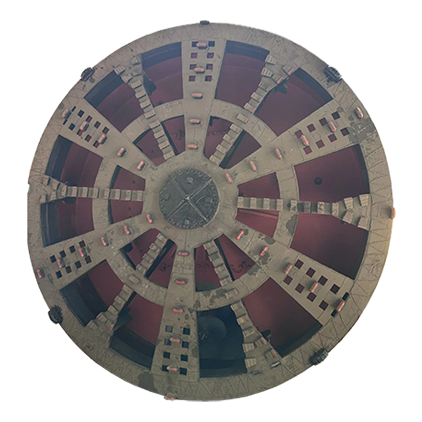

5. The cutting disc adopts Q355B steel plate, and alloy blades are installed on the complete trajectory line, which is wear-resistant and efficient.

6. The power is driven by an AC motor, planetary reducer, and gearbox, achieving high torque power output. High transmission efficiency, providing continuous power support for the pipe jacking machine.

Model: BKJD6900 × 4900

Model meaning: BK (Baokun) JD (earth pressure balance pipe jacking machine) 6900 × 4900 (square pipe with an outer diameter of 6900 × 4900)

Example: TPD3400

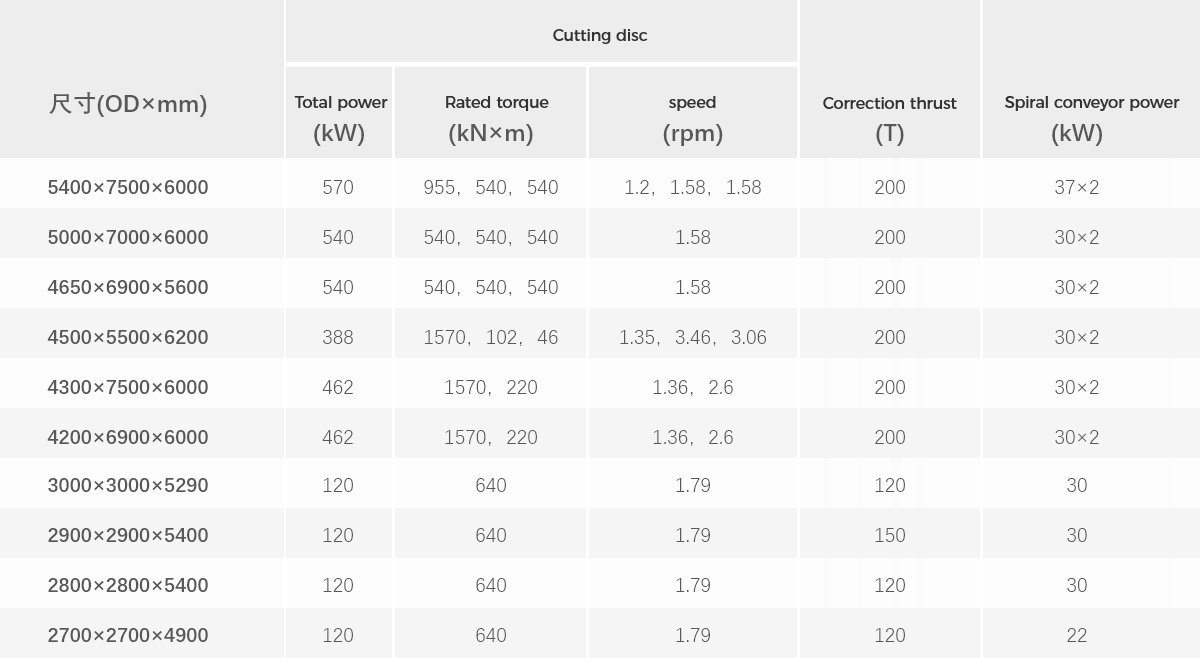

Technical Parameter