Rock Breaking Pipe Jacking Machine

1. Suitable for rock formations, pebble formations, and other rock containing formations, with diameters ranging from D800 to D5200.

2. During top-down construction. The excavation face is stable, with high power torque and the ability to easily crush rock layers with hard alloy rolling cutters. The cut stones will enter the crushing chamber and undergo "secondary" crushing to further break into small crushed stones, thus achieving excavation inside the rock layers

3. Using a water pump to transport clean water or a suitable proportion of mud and water into the top cutting surface, combined with the rotating cutting of the cutting disc, the crushed stone from the secondary crushing is pumped to the surface through a pipeline by the mud pump, resulting in high efficiency and fast construction speed for continuous top cutting

4. There is a manhole inside the cabin, which allows access to the cutterhead for changing cutting tools and repairing. Achieve long-distance construction jacking.

4. Adopting advanced industrial control technology to achieve remote safe operation. Through the PLC data link, the operating system safely controls the pipe jacking machine on the ground and real-time observation equipment for real-time data underground.

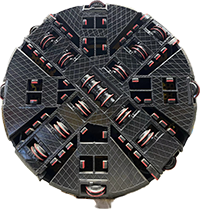

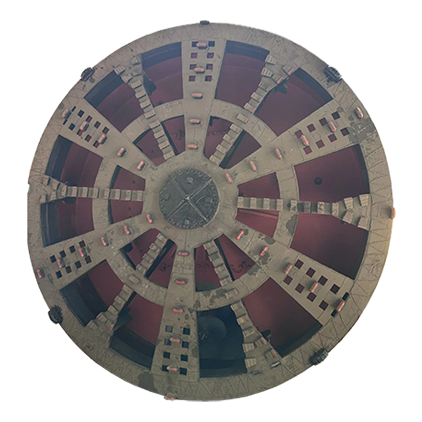

5. The cutting disc is made of Q355B steel plate and thickened broken "cow legs" to form a sturdy and strong cutting disc. Install replaceable rolling cutters and arc scrapers on the complete trajectory line.

6. The power is driven by an AC motor, planetary reducer, and gearbox, achieving high torque power output. High transmission efficiency, providing continuous power support for the pipe jacking machine.

Model: BKYD2000-G

Model meaning: BK (Baokun) YD (rock crushing pipe jacking machine) 2000 (cement pipe with an inner diameter of 2000) - G refers to steel pipes of this diameter.